GWEIKE Introduces M Series 6-in-1 System Combining Cutting, Welding, Cleaning, and More in One Platform

GWEIKE M Series integrates six laser functions in one platform, helping shops reduce equipment footprint and simplify multi-process production.

NY, UNITED STATES, January 8, 2026 /EINPresswire.com/ -- As the global manufacturing sector grapples with rising operational costs, a chronic shortage of skilled labor, and the urgent need for sustainable production, Gweike, a pioneer in laser technology for over two decades, has announced the definitive solution: the M Series 6-in-1 Laser Processing Platform.

This document explores the technical architecture, economic impact, and strategic importance of the M Series—a machine that integrates Fiber Laser Cutting, CO2 Laser Engraving, Handheld Welding, Laser Cleaning, Handheld Cutting, and Remote Welding into a single, cohesive industrial ecosystem.

The Strategic Shift: Beyond Single-Function Machinery

For decades, the factory floor has been a landscape of fragmentation. A typical metal fabrication shop required a CNC fiber laser for sheets, a CO2 laser for non-metallic components, a dedicated station for TIG/MIG welding, and a messy chemical or abrasive area for rust removal. This "fragmented workflow" results in three major bottlenecks:

· Space Inefficiency: Each machine occupies premium real estate.

· Workflow Friction: Moving workpieces between stations increases the risk of damage and extends lead times.

· Capital Deadweight: Small-to-medium enterprises (SMEs) must invest in four separate power systems, cooling units, and control interfaces.

The Gweike M Series eliminates these barriers. By consolidating these functions, Gweike offers a "Micro-Factory" in a single footprint, allowing manufacturers to pivot between diverse tasks—from industrial metal cutting to delicate wood engraving—without changing machines.

The Core Innovation: Dual-Source Synergy

The M Series is the first of its kind to successfully master Dual-Source Integration. Unlike hybrid machines that compromise on power, the M Series features a dual-optical path system:

· The Fiber Laser Engine (1200W): Optimized for high-reflectivity metals. It delivers a positioning accuracy of $\pm0.02mm$, capable of slicing through 10mm carbon steel or 5mm stainless steel with industrial-grade precision.

· The CO2 Laser Engine (130W): Designed for the "soft" side of manufacturing. It handles acrylics, wood, leather, and fabric, providing the high-contrast engraving and smooth edges that fiber lasers cannot achieve on organic materials.

This synergy allows a user to, for example, cut a precision steel bracket and then immediately engrave a serialized wooden handle or acrylic shield for the same product, ensuring $100\%$ design consistency.

Technical Masterclass: A Deep Dive into the 6-in-1 Versatility

The brilliance of the Gweike M Series lies not just in the combination of tools, but in the uncompromising performance of each individual function. Below is a technical breakdown of the six pillars that define this platform.

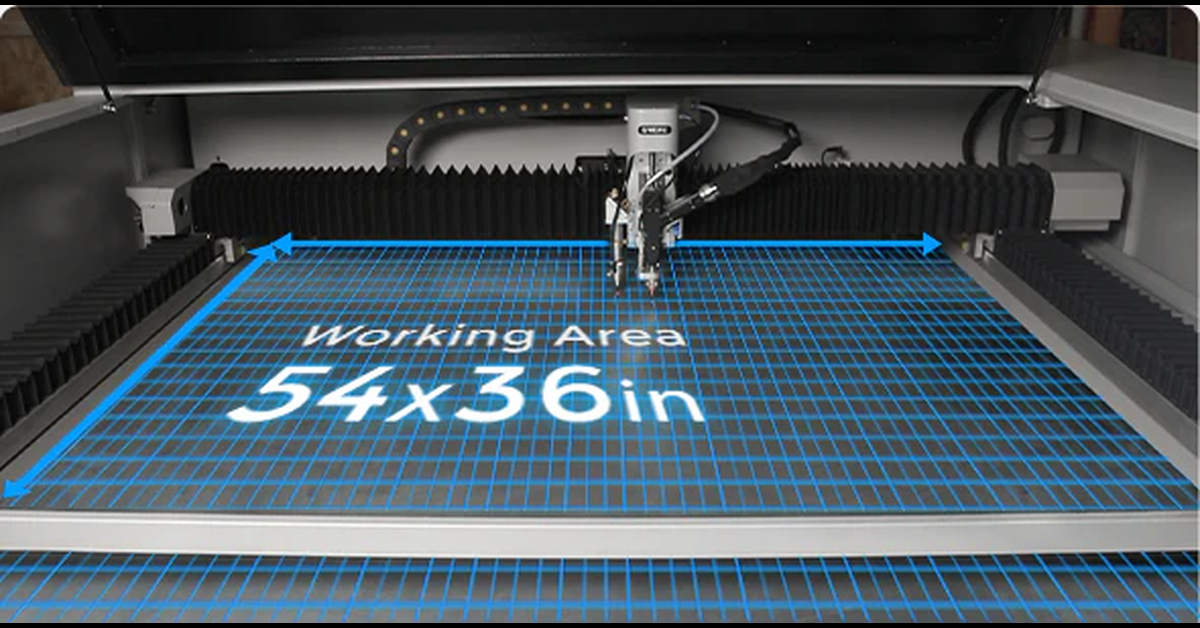

1. Industrial CNC Fiber Laser Cutting

The foundation of the M Series is its high-precision CNC cutting capability. Powered by a 1200W fiber laser source, it utilizes a sophisticated gantry system with high-strength aviation aluminum beams.

· Precision and Speed: Unlike entry-level cutters, the M Series maintains a positioning accuracy of $\pm0.02mm$ even at high speeds of $800mm/s$.

· Material Range: It is engineered for the "Big Four" of metal fabrication: Carbon Steel (up to 10mm), Stainless Steel (up to 5mm), Aluminum, and Brass.

· The "Smart" Edge: The system features Active Obstacle Avoidance, which uses high-frequency sensors to detect plate warping in real-time, instantly adjusting the laser head height to prevent collisions.

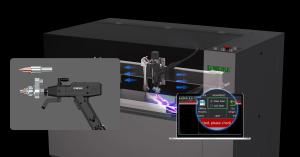

2. Handheld Fiber Laser Welding

The M Series transforms into a powerful handheld welding station, designed to replace traditional TIG and MIG welding.

· The "Wobble" Technology: The handheld gun features a motorized "wobble" head that oscillates the laser beam. This creates a wider weld seam and allows for better tolerance on irregular gaps, resulting in structural integrity that often exceeds the base material.

· Ease of Use: Because the laser delivers concentrated heat, the Heat Affected Zone (HAZ) is minimal. This prevents thin sheets (like 1mm stainless steel) from warping or discoloring, reducing the need for post-weld polishing by $80\%$.

· Speed Efficiency: It operates at speeds up to 10 times faster than traditional manual arc welding.

3. Non-Metallic CO2 Laser Cutting & Engraving

This is the M Series’ unique competitive advantage—the integration of a 130W CO2 glass tube.

· The Hybrid Advantage: While fiber lasers are reflected by non-metals, the CO2 source is perfectly absorbed by organic materials. This allows the M Series to cut through 25mm wood or 20mm acrylic with glass-like edge finishes.

· Precision Engraving: The CO2 module is capable of high-resolution engraving on leather, fabric, and coated glass, making it indispensable for manufacturers who need to add branding, serial numbers, or aesthetic patterns to their products.

4. High-Energy Laser Cleaning

Environmental and safety regulations are making chemical pickling and sandblasting obsolete. The M Series offers a sustainable alternative through its laser cleaning mode.

· Ablation Principle: The laser emits high-intensity pulses that cause rust, oil, oxides, and paint to undergo thermal expansion and sublimation.

· Substrate Protection: The parameters are tuned so that the laser interacts only with the contaminants, leaving the underlying metal substrate completely undamaged and "active" for immediate painting or welding.

· Cost Savings: It eliminates the recurring costs of consumables like sand, chemicals, and specialized disposal services for hazardous waste.

5. Portable Handheld Laser Cutting

While the CNC gantry is perfect for precision, some jobs are too large or awkwardly shaped to be placed on a machine bed.

· Flexibility on Demand: The M Series allows the operator to switch to a handheld cutting mode. This is a "game-changer" for on-site maintenance and demolition.

· Large-Scale Fabrication: Whether it’s trimming a pre-installed metal panel or cutting through a large steel pipe in a construction setting, the portable cutting function ensures the machine’s utility extends far beyond its physical dimensions.

6. Remote Laser Welding & Specialized Surface Treatment

The sixth function delves into the realm of advanced industrial processing.

· Remote Processing: Utilizing a long-focal-length optical setup, the M Series can perform "remote welding"—welding joints from a distance without the nozzle touching the workpiece. This is critical for complex 3D structures or areas with limited physical access.

· Surface Modification: Beyond cleaning, the laser can be used for surface roughening or quenching, altering the surface tension or hardness of the metal to prepare it for high-strength adhesive bonding or to increase wear resistance in high-friction environments.

Smart Manufacturing: Software & Safety

Hardware is only as good as the software governing it. The M Series runs on Gweike Cloud AI, which features:

· Active Obstacle Avoidance: Using ultrasonic and optical sensors, the laser head detects tilted metal plates in real-time, preventing collisions that could cost thousands in repairs.

· Cloud Parameter Library: Users have access to a cloud-based database of over 100 material settings, removing the guesswork from power and speed adjustments.

· 30-Second Mode Switching: The transition from CNC cutting to handheld welding is engineered to be tool-free and intuitive, minimizing downtime between different production phases.

Economic Analysis: ROI in the Modern Factory

For a business owner, the M Series is a financial strategic move. A comparative analysis shows:

· CAPEX Reduction: Buying one M Series costs significantly less than buying four separate high-end machines for cutting, welding, cleaning, and engraving.

· Energy Savings: Integrated cooling systems and optimized power supplies reduce electricity consumption by an estimated $35\%$ compared to running multiple independent machines.

· Labor Efficiency: A single operator can manage the entire fabrication cycle, reducing the "per-part" labor cost by nearly half.

Sustainable Manufacturing (ESG Compliance)

Gweike is committed to the "Green Factory" initiative. The M Series contributes to ESG goals by:

· Eliminating Chemicals: Laser cleaning removes the need for hazardous acids and solvents.

· Reduced Waste: Precision nesting minimizes scrap metal.

· Fume Extraction: Built-in high-volume filtration ensures a safe, clean breathing environment for workers, exceeding international OSHA standards.

Founded in 2004, Gweike is a global titan in laser manufacturing, serving over 150 countries. With a massive $40,000 m^2$ production facility and a team of over 200 R&D engineers, Gweike continues to push the boundaries of what is possible in photonics and industrial automation. The M Series is the latest testament to Gweike’s mission: To make high-end laser technology accessible to every creator and manufacturer on earth.

Allison

GWEIKE Laser Equipment Co., Ltd.

+86 132 5337 0724

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

TikTok

X

Gweike M Series CNC Fiber & CO₂ Laser System

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.